视频播放 笛子的制作方法Method of making flute

360U190016136812级分类:

器乐声乐被浏览877次2015.07.17

360U1901973070

采纳率:50%12级2015.07.18

1.制作工具:

(1)能够切断竹子的小锯或刀子;

(2)能够钻眼(孔)的钻子或者粗铁丝(烧红)之后钻孔用;

(3)修挖洞孔的小尖刀(普通小尖刀也可以);

(4)能够打穿竹子内的长刀,或用粗钢丝把一头打成半圆形,磨得锋利一些即可;

(5)铅笔和小米达尺。

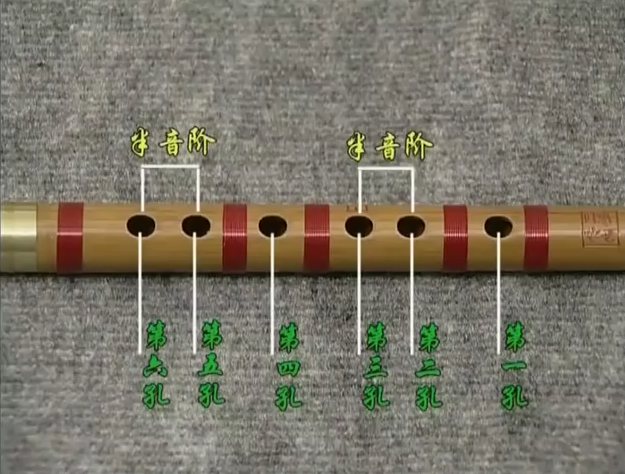

2.竹子的粗细和音孔、膜孔、吹孔距离的比例,可参阅下面的图表:

3.制作过程:

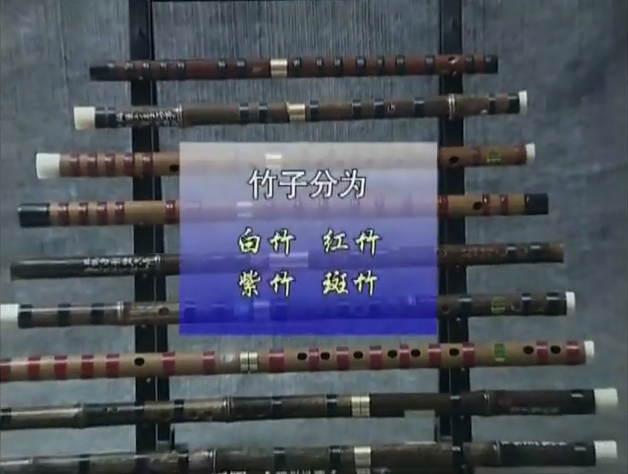

(1)首先把竹子的材料选好。一般说,要选用老的、坚实而干燥的竹子,其次是竹节要小(多少不太紧),表面圆而平整,两头的粗细相差不大。选好之后,按笛子的长度锯成节。如果竹身不直,可用柴火(或草火)烘烤,把有弯的地方烤热后,扳直浸入冷水中(以防弯度复原),待冷却后拿出来擦干即可。

(2)打通内节,削平外节内外都要尽量求得光滑。如果竹皮粗糙而不美观也可以刮去一层薄皮。

(3)比量尺寸,决定调子。把竹子材料弄好以后,量一下内经(直径)和长度,根据它的粗细和长短,决定做什么调子的笛子最合适。

(4)调音和挖孔。这是做笛子全部过程中最重要也是最困难的一步工作。往往因一个孔挖得不合格(发音不准)而使全笛报废。

挖孔时,首先挖好吹孔(不可挖得太大),堵上笛塞(也可以利用某个竹节不打通,来作笛塞),然后量好吹空孔至后音孔的距离,挖两个后出音孔。开始要先挖小点,然后吹一吹,听一听,看看筒内音是否准确?如果低了点,就将两个孔都向前(向吹孔那边)挖大一些,也可以不再挖。要特别注意的是,开始挖孔时不能超过规定的尺寸,以防音孔开高了不好弥补。

把后出音孔挖好后,以此孔为基点,朝着吹孔方向按顺序,按尺寸比例依次挖孔。挖的方法也是先挖小点,然后边试音,边扩大。挖好一孔再挖另一孔,最后挖膜孔。两头多余的竹子先锯掉或后锯掉都可以。如果笛尾竹子长,还可开两个前出音孔(又称调音孔),也可以将笛尾锯短一些,不要前出音孔。

全部工序完后,进行总的校对和检查,最后上漆。这样,一支新笛子就算完全制成了。

Production process of traditional instruments Chinese bamboo flute

(1) a saw or knife capable of cutting off bamboo;

(2) to drill hole (hole) drill or thick wire (red) after drilling;

(3) digging holes in the small knife (ordinary small knife can also be);

(4) to break through bamboo knife, or with a thick steel wire head in a semicircle, some can be sharpened;

(5) pencil and millet reach the ruler.

- bamboo hole, hole, film thickness and blow hole distance ratio, can refer to the chart below:

- making process:

(1) first, choose the materials of bamboo. Generally speaking, we should choose the old, solid and dry bamboo, and then the bamboo should be small (not too tight), the surface is round and smooth, and the thickness of the two sides is not big. After you have chosen, cut the knots according to the length of the flute. If the body is not straight bamboo, firewood available (or grass fire) to the local bending baking, baking hot, straight plate immersed in cold water (in the case of camber recovery), after cooling out to dry them.

(2) in the open section, flattened outer segment both inside and outside to try to obtain a smooth. If the bamboo skin is rough and unsightly, it can also scrape a thin layer of skin.

(3) the proportion of size, decided tone. After making the bamboo material, measure the internal diameter and length of the bamboo, and determine the proper pitch of the flute according to its thickness and length.

(4) tuning and digging holes. This is the most important and the most difficult step in the process of doing flute. Often due to a hole dug unqualified (pronunciation is not allowed) and the whole flute scrapped.

Dig holes, first dug holes (not too large, dig) block is (you can also use a bamboo is not open, then, is to make a good amount of air blowing) after the hole to hole distance, dig two holes after. Began to dig down, then blowing, listen, look at the drum sound is accurate? If the point is lower, the two holes are forward (to the side of the blowing hole) to dig bigger or not to dig any more. We must pay special attention to, can not exceed the size to start digging holes, to prevent high bad make up.

After the holes dug this hole, as the starting point toward the blow hole direction in order, according to the size and proportion in order to dig hole. The method of digging is also to dig small points, and then try to sound, while expanding. Dig a hole, dig another hole, and finally dig the membrane hole. Two extra bamboo or can be sawed off after the first cut off. If the long tail bamboo flute, also can open two pairs of holes (also called holes can also be adjustable), foot cut short, don’t sound out.

After the completion of the whole process, the total proofreading and inspection, the final painting. In this way, a new flute is made completely.

视频来源网络 !如有侵权 ,请联系删除 论点和本频道无关

Video source network! If there is infringement, please

contact delete.

未经允许不得转载:環球樂器博览网 » 中国乐器 笛子的制作工艺 视频详解

環球樂器博览网

環球樂器博览网

评论前必须登录!

登陆 注册